(last updated 2023)

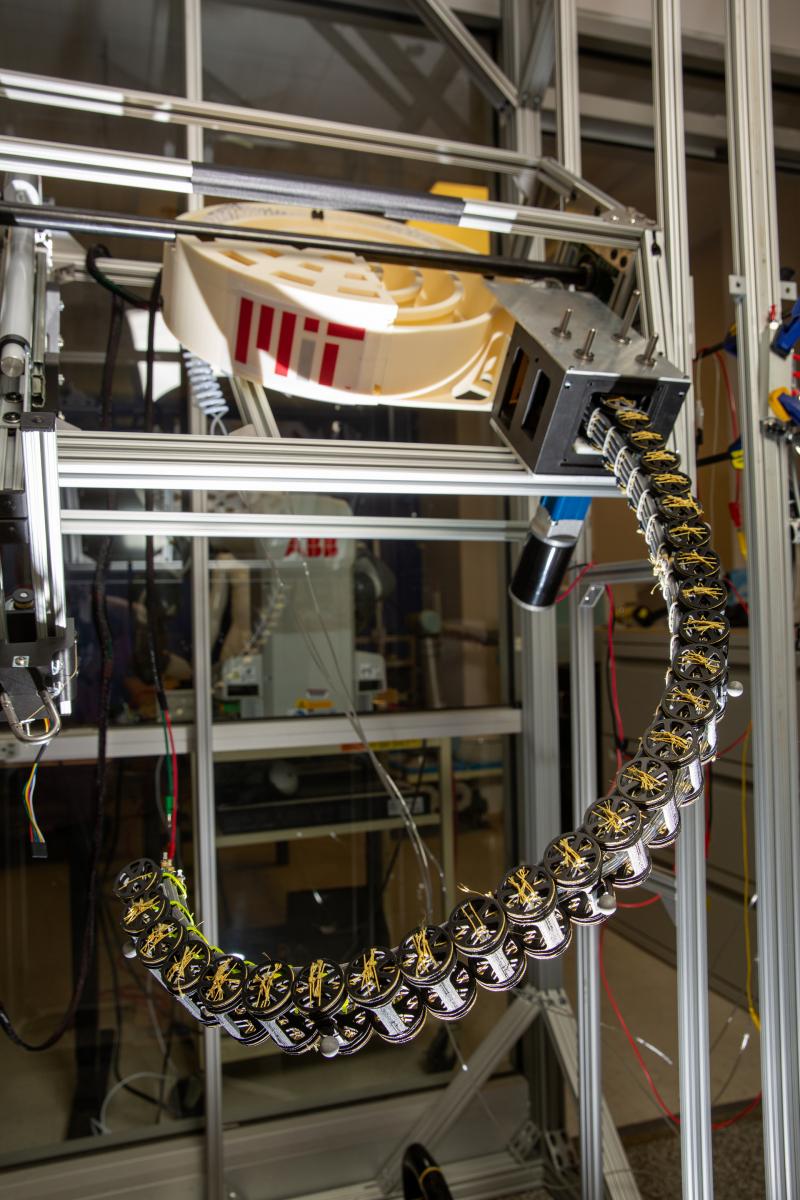

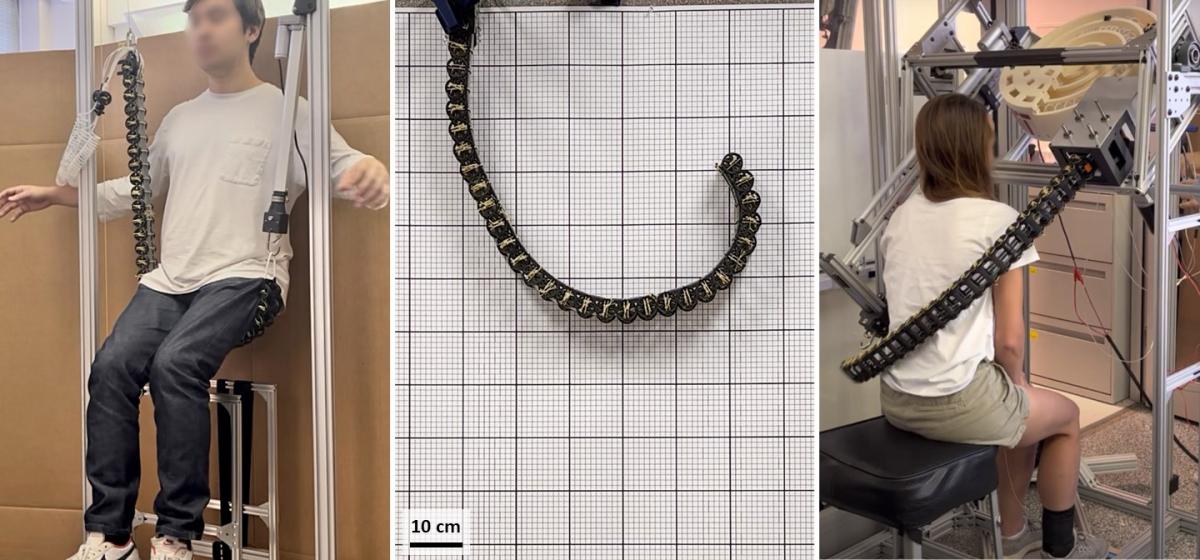

ROBOTIC STRAP

* Temporary project webpage: darbelofflab.mit.edu/robotic-straps.

* In the meantime, please refer to this TUTORIAL for initial fabrication files/instructions, and/or contact kbarhydt@mit.edu for any questions/comments related to this project.

* Project paper: ieeexplore.ieee.org/document/10048528

Safely harnessing and lifting humans for transfer is a challenging unsolved problem for current robots because of the high forces and gentle interaction necessary to do so. Humans are heavy, delicate, deformable, and vary widely in shape and pose. Standard robotic manipulators and end-effectors cannot achieve sufficiently gentle human interaction while applying the high forces needed to lift the body effectively, although many high impact tasks depend on this functionality. Straps, however, are highly beneficial for manually performing this task primarily because of their simultaneously high tensile strength and high compliant bending flexibility, in that (1) the high tensile strength allows for load bearing capacities great enough to lift the full weight of the human, and (2) the high bending flexibility allows for the high passive compliance and conformity needed to safely distribute these large forces across the body.

We present the Robotic Strap, a novel concept and design for a new type of manipulator that can passively harness and lift humans safely as straps can, as well as actively articulate itself around the human into the desired harnessing configurations. The Robotic Strap manipulator is the first robot to demonstrate automatic harnessing and lifting of a human above the ground. The design is characterized by the high tensile strength and bending flexibility of straps, and its implementation consists of a hyper-articulated backbone with rolling-contact joints and embedded soft pneumatic artificial muscles. In our paper, “A High-Strength, Highly-Flexible Robotic Strap for Harnessing, Lifting, and Transferring Humans", we present the concept, framework, realization, and implementation of the Robotic Strap design, as well as model and experimentally validate the key characteristics. The prototype has a tensile load capacity of 1314.0 N, a maximum joint bending resistance of <0.1 Nm, and successfully demonstrated safe and effective harnessing and lifting of three human participants without any manual intervention. This new manipulator design paradigm unlocks significant advances in robotic handling of heavy yet gentle objects, enabling new capabilities in important applications such as elderly care, occupational therapy, emergency medical response, search and rescue.

Bipedal Walking Control for Stable Global-Position Tracking

I worked as a visiting scholar with Dr. Yan Gu on bipedal walking control and simulation. I assisted the development of a trajectory tracking controller for multi-domain hybrid models of bipedal walking based on control Lyapunov functions and quadratic programming.

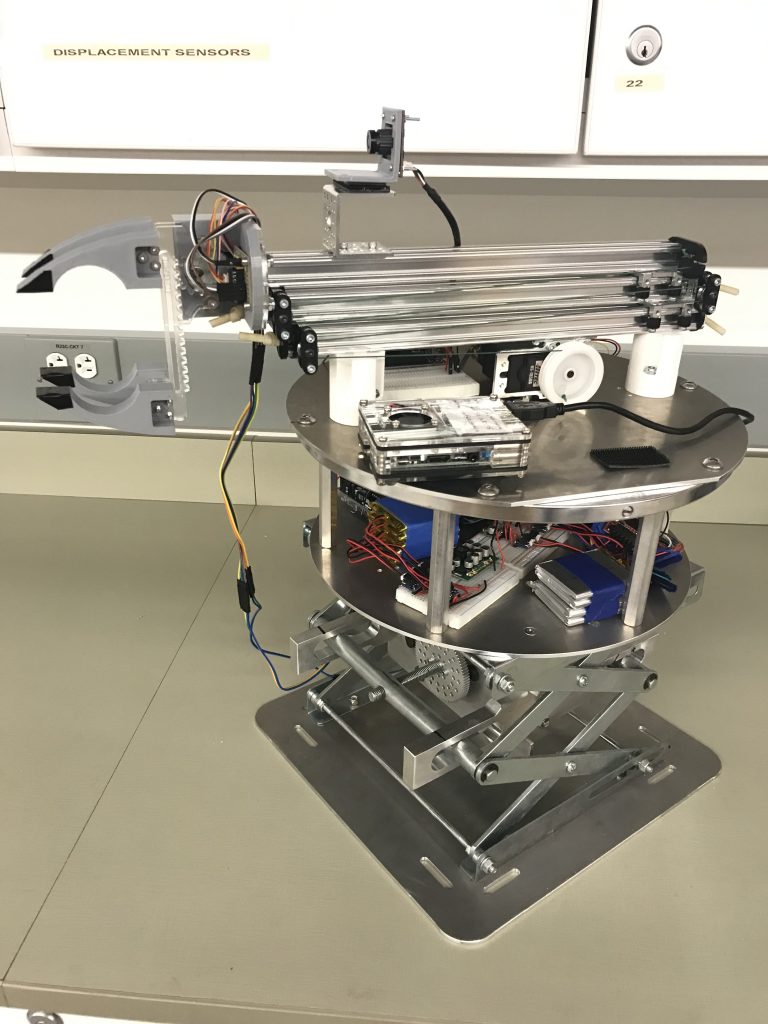

ASSISTIVE ROBOTICS PLATFORM DESIGN FOR USER AGENCY, PERSONALIZATION, AND ACCESSIBILITY

- (left to right) Cylindrical Manipulator, Cartbot Prototype

I worked as a research assistant with Dr. William Messner on the design and development of an assistive robotic platform for people with physical disabilities during my first year at Tufts University. I developed a teleoperated assistive mobile manipulator based on a minimal-DOF design approach I formulated. This approach allows direct-manipulation control to maximize the user’s agency over its behavior while maintaining sufficient functionality. With the goal of developing a practical platform that could be accepted into people’s everyday lives, I developed the project by formulating a direction that addressed the relationship between the system’s DOF and the user’s control agency. I collaborated with the Tufts Occupational Therapy department to conduct multiple user studies with participants with tetraplegia to evaluate the performance and usability of the platform.

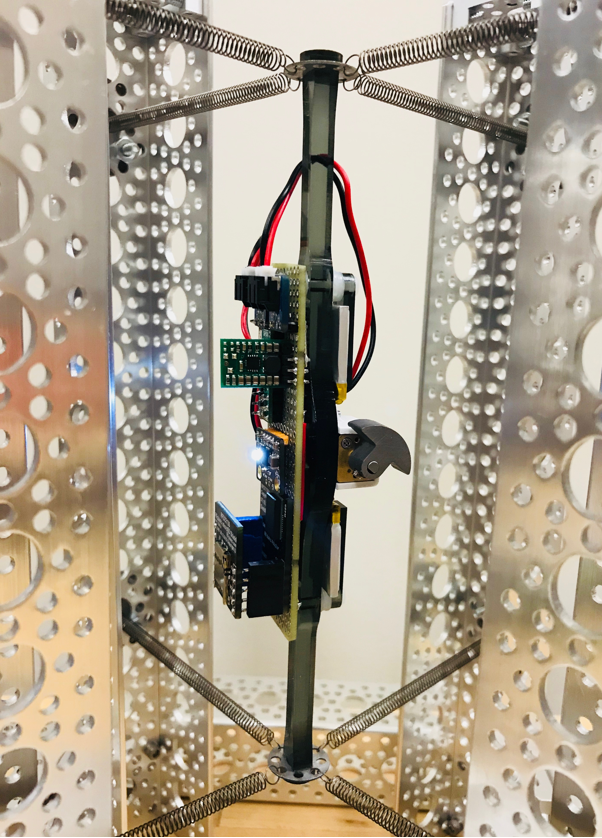

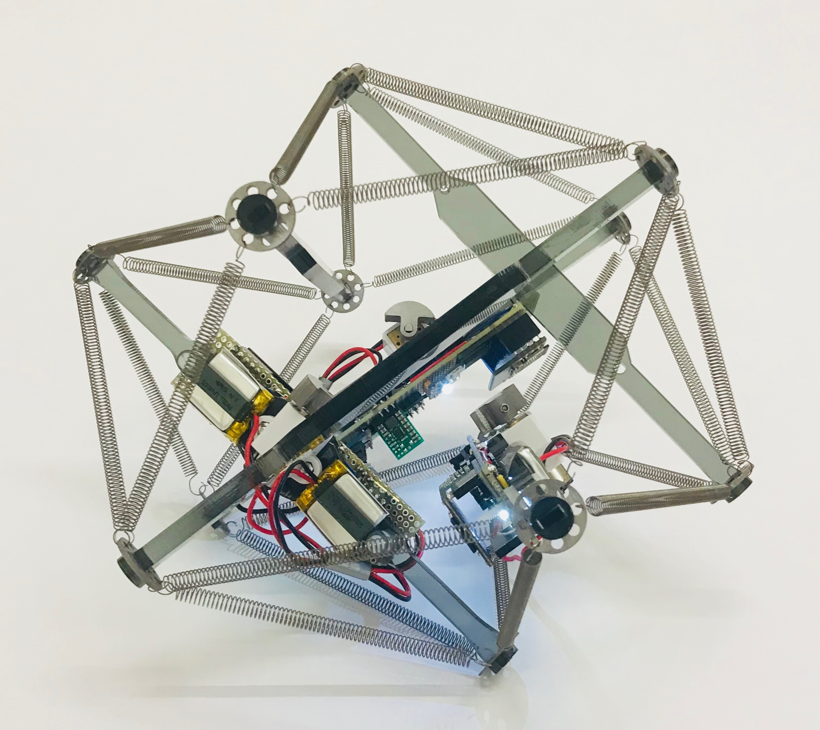

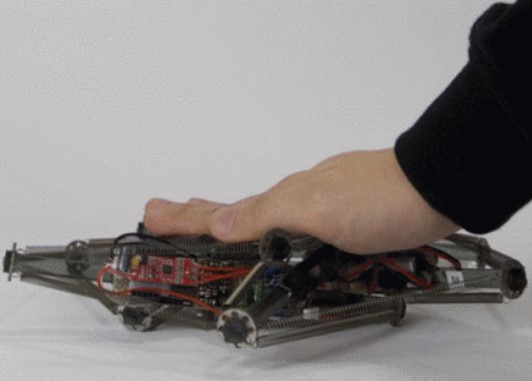

WIRELESS VIBRATING TENSEGRITY ROBOT

- Showcase video for first prototype of wireless vibrating tensegrity robot

- (left to right) Wireless tensegrity strut module in resonance testing apparatus, Assembled 6-bar tensegrity robot (3 active struts)

I designed and developed a wireless vibrating tensegrity robot during my junior and senior years of my undergraduate at Union College as a part of Dr. John Rieffel’s research on evolutionary robotics and morphological communication. The strut modules were designed to excite the resonant frequencies of the robot.

- Designed, modeled, fabricated, and tested a wireless vibrating tensegrity strut to complete the world’s first wireless vibrating tensegrity robot, which serves as a reliable and modular test subject for genetic algorithm experiments.

- Designed for rapid manufacturing (only necessary fabrication processes are: laser cutting, waterjet cutting, and soldering)

- Developed a resonance model of a single strut to validate the FEA model for the resonant modes of the robot.

- Designed a custom vibration motor to match the resonant frequency range and maximize amplitude.

- Implemented onboard IMU and data collection for motion tracking of individual struts during locomotion.

VR & AR APPLICATIONS FOR DESIGN AND MANUFACTURING (GE Global Research, R&D Internship)

- Researched and tested a diverse range of current virtual reality (VR) and augmented reality (AR) technologies for innovative applications in engineering design and manufacturing

- Developed interactive VR simulations using Unity3D to create virtual environments and program behavior components for the purpose of establishing proof-of-concept for use cases relevant to the project